Introduction

Tea bag filter paper rolls have become an indispensable component in modern tea packaging, combining precision engineering with food-grade safety to enhance brewing efficiency and product quality. Designed for compatibility with automated packaging systems, these rolls are transforming the tea industry by offering customizable solutions that meet global hygiene and performance standards. Below, we delve into their key advantages and technical features, supported by innovations from leading manufacturers.

Advantages of Tea Bag Filter Paper Rolls

1.Superior Material Composition and Safety

Made from a blend of wood pulp and abaca pulp (a natural fiber derived from banana plants), tea bag filter paper rolls ensure high breathability and strength while retaining the tea’s original flavor, color, and aroma. The use of food-grade materials, including imported long-fiber pulp and heat-sealable fibers, guarantees compliance with stringent certifications such as ISO, FDA, and SGS, making them safe for herbal, pharmaceutical, and food applications.

2.Enhanced Brewing Performance

These rolls feature optimized porosity, allowing rapid infusion of tea without releasing fine particles into the beverage. For example, 12.5gsm variants maintain clarity by retaining tea dust while enabling quick hot water penetration. Higher GSM options (16.5–26gsm) cater to diverse brewing needs, balancing infusion speed and residue filtration.

3.Heat-Sealing Reliability

Designed to withstand temperatures above 135°C, the paper forms secure seals during packaging, preventing leaks or breakage even in high-speed machinery like Italy’s IMA or Argentina’s MAISA systems. This thermal resistance ensures consistent product integrity across production lines.

4.Customization and Adaptability

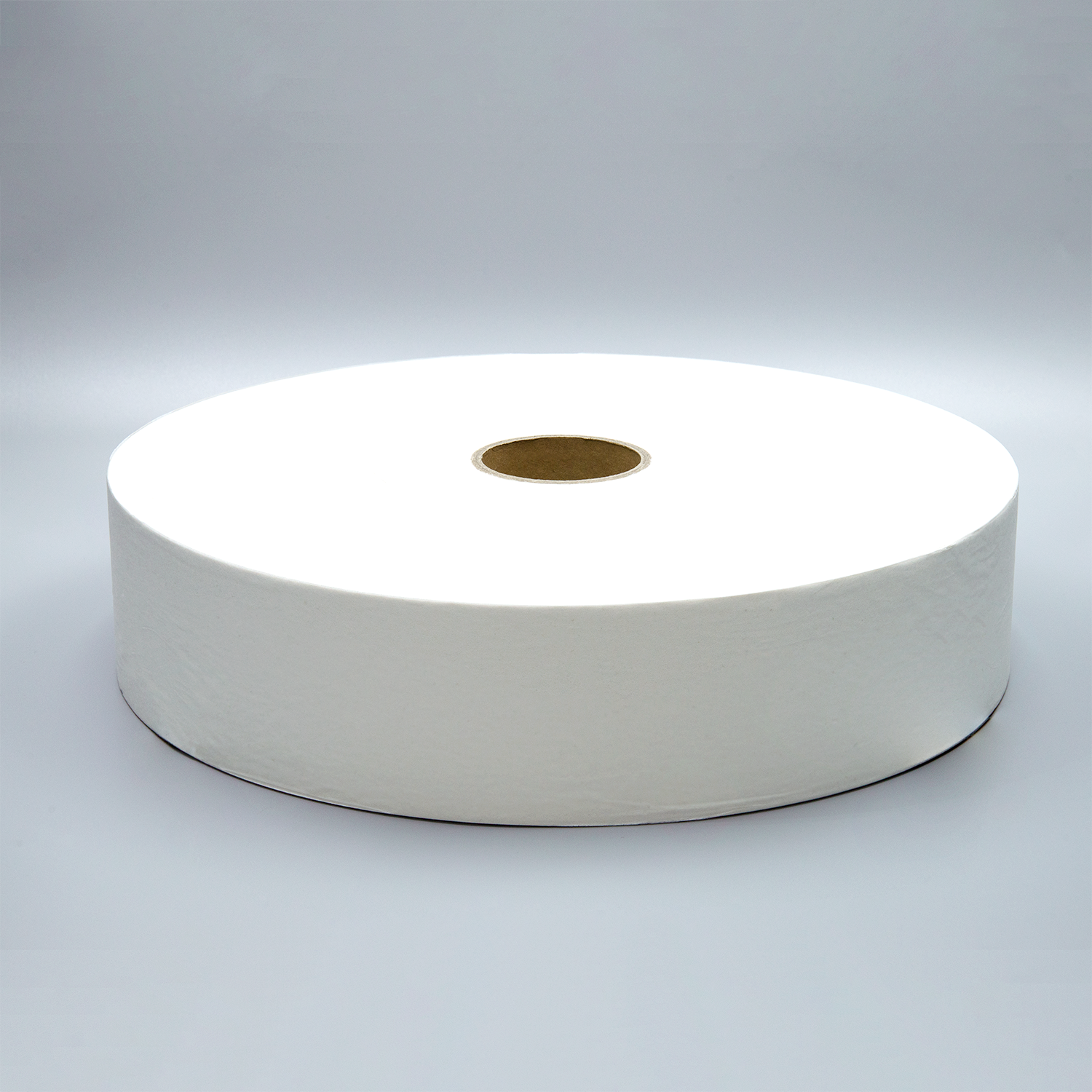

Manufacturers offer rolls in widths ranging from 70mm to 1250mm, with core diameters of 76mm and outer diameters up to 450mm, tailored to fit specific machine requirements. Customizable GSM levels and heat-sealable/non-heat-sealable options further enhance versatility for niche applications, such as traditional Chinese medicine sachets or powdered seasoning packs.

5.Cost-Efficiency and Sustainability

Bulk production (MOQ 500kg) and recyclable packaging (polybags + cartons) reduce waste and costs. The absence of non-food additives aligns with eco-conscious trends, while compostable abaca pulp supports circular economy goals

Technical Features Driving Industry Adoption

- Strength and Durability: Dry tensile strength of 1.0 Kn/m (MD) and 0.2 Kn/m (CD) ensures resistance to tearing during high-speed packaging . Even when soaked in hot water for 5 minutes, wet tensile strength remains stable (0.23 Kn/m MD, 0.1 Kn/m CD), preserving bag integrity during brewing

- Moisture Control: Maintains a moisture content of 10%, preventing brittleness or mold growth during storage

- Machine Compatibility: Compatible with global machinery brands, including Germany’s Constanta and China’s CCFD6, ensuring seamless integration into existing workflows

- Rapid Turnaround: Samples are available within 1–2 days, with bulk orders delivered in 10–15 days via air or sea freight

Post time: Feb-25-2025